The core reason to consider outsourcing manufacturing for any company is to gain a competitive advantage in the market place. There are numerous reasons for partnering with a manufacturer and many reasons to choose one over the other. The team at E4D Technologies is here to help walk you through the reasons why contract manufacturing could be a good decision for your business. Here are a few things to consider before you sign a contract:

The Financial Benefits of Outsourcing Manufacturing

First and foremost, outsourcing isn’t the ultimate solution to saving money. Sometimes, it doesn’t make fiscal sense to outsource at all. In other situations, outsourcing might be the best decision. One strong reason to consider outsourcing is to address gaps in your business’ capabilities. Finding the right contract manufacturer can create a hybrid approach where each organization plays to its strengths and helps save the expenses from duplicating those resources in-house that may not be needed long term. Often the ROI doesn’t make sense when the skills and resources exist with the outsourcing partner. If you have available capacities in both facilities and people, outsourcing may not be right for you at this time.

The Case for Resources or Skill Gaps

One common gap that can be solved through outsourcing is related to capacity. You may not have any manufacturing facilities, and the costs to build and fit-out space is not a good ROI. You might not have enough space or capacity, and so instead of using capital to increase the manufacturing space, you can partner with an existing factory at an outsourcing company.

You might also have a gap with specific skills. Perhaps you need support with a design project and your core design team is overbooked, or there is a unique technical skill required for the project that is not part of your core team. Finding a full-service contract manufacturer like E4D Technologies can help your company solve those problems. A full-service manufacturing team consists of individuals who have all the disciplines needed for global supply chain manufacturing and management. If you’re looking for a partner who will help you every step of the way, our team is here to help you with all of your manufacturing needs.

What Is the Outsourcing Partner Security and Confidentiality around Your Products and Intellectual Property?

Protecting your Intellectual Property (IP) is important, and having trust in your manufacturing partner is critical. As you consider who should be your outsourcing partner, you need to understand how they manage and protect customer propriety and confidential information (including your IP). You should also expect to clearly see defined responsibilities and ownerships of intellectual property (IP) in your contract. Typically, the manufacturer will own their methodologies and processes around the manufacturing system, and the customer will own the product’s IP.

Reputation, experience, and capabilities are some of the major factors you have to consider when choosing a partner. Some of the questions you should ask yourself and your team when deciding on contract manufacturing companies are:

- What do other people say about the manufacturer?

- Do they have the reputation of protecting their customer’s data?

- How long has the company been manufacturing products?

- Does the manufacturer have controls in place that keep the customer and the IP safe?

- Is their factory open for you to visit?

- While touring the factory, how do you feel about the protection of other client products by the manufacturer?

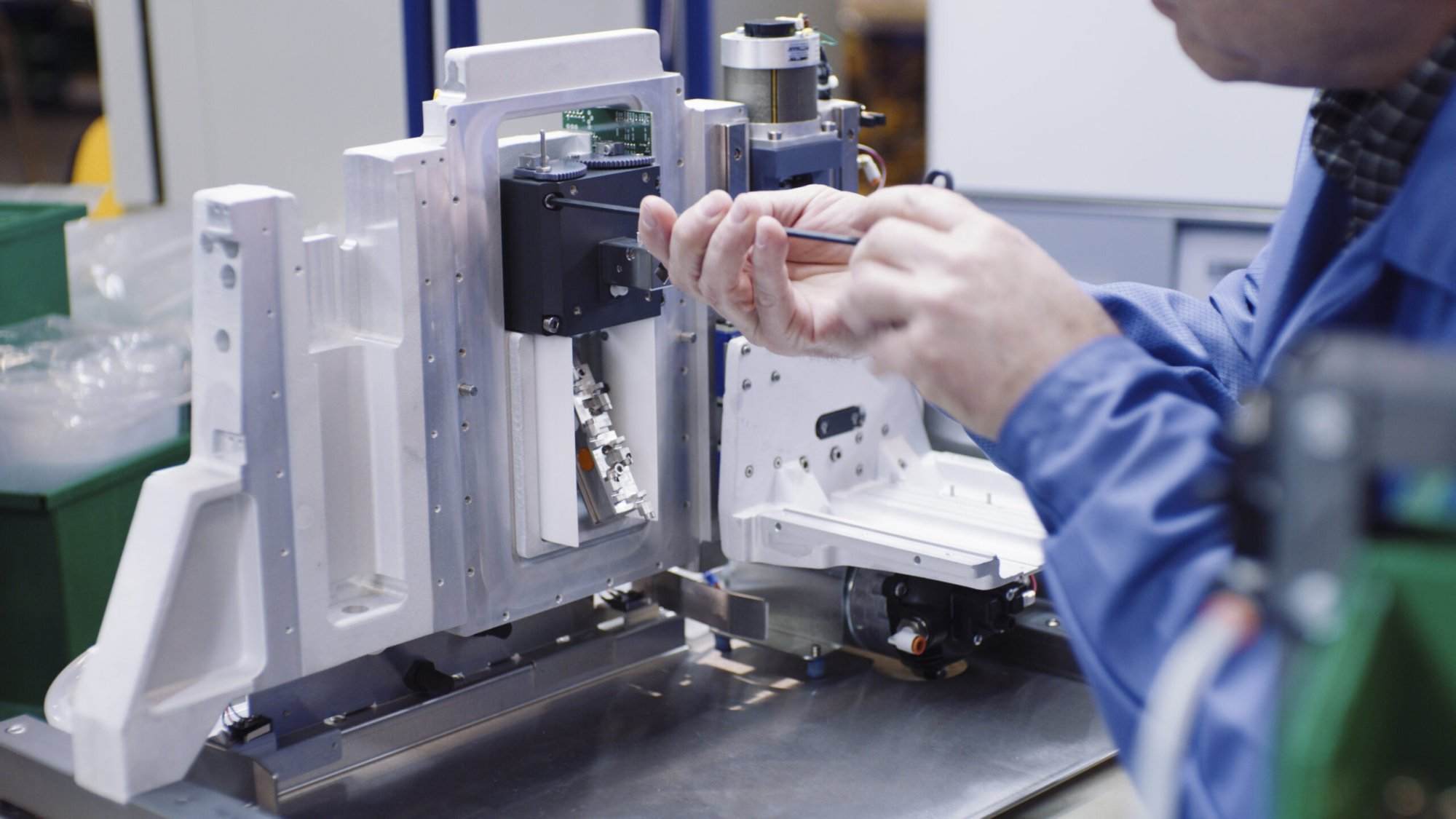

As an outsourcing partner who has both their own IP and has managed and protected our customer’s IP, we know that IP protection is essential for any partnership. That’s why the team at E4D Technologies has specific protocols and safety guards to make sure our client’s IP is safe 24/7. Our team consists of highly-skilled and talented manufacturers who give our company the feel of a large manufacturer but gives our clients the customer care of a small contract manufacturer.

How Aligned Is the Contract Manufacturer with your Products, Requirements and Size?

Another factor to consider when thinking about outsourcing manufacturing is who will be the best fit for your needs. When deciding which contract manufacturer to partner with, you might want to review the median size of companies that they work with, the types of products they currently support and any regulatory experience they have that could align with your product needs.

Since many manufacturers work within a specific industry, a lot of their capabilities and processes might be similar to the way your competitors build their products. Working with the same manufacturer that your competitors work with might give you an advantage or allow you to operate on the same playing field. The manufacturer will know how to produce your product giving you the high-quality advice you need while supplementing the experience you lack. If you do not want your outsourcing partner to manufacture in the same space as your competitor, you might be able to negotiate that in your contract. However, most contract manufactures gain their leverage by working on several similar or competing products. The crucial factor is if they protect all of their customer’s information and IP. If so, it should not be a concern if they have competitive products. Alternatively, you might be able to request that the same teams of engineers don’t work on the competitor products even if they are built in the same factory.

Lastly, the benefit has to outweigh the cost. As stated before, the price increases with the more exclusivity you want with a manufacturer. Yes, outsourcing can help with labor costs, expertise gaps, and factory space, but will it make fiscal sense for your company? In some cases, it might make sense to build specific parts of your product on your own while outsourcing other components. When it comes to our team, we have ample experience working with highly-complex products from anywhere from medical device manufacturing to product design. Our team is here to help walk you through everything you should consider while choosing a contract manufacturer, and we’re willing to help you determine the best ROI for your product.

As a full-service contract manufacturer, we’re capable of handling the outsourcing manufacturing needs of many businesses. Our team is here to help you whether you need someone to reverse engineer, help you with your sketch to scale or manage your product life cycle. We can help companies in many industries, including optical, industrial, mechanical, medical, and software. For more information about our company, and to see if we’re the right fit for you, contact our team today.

Photo Sourced from E4D Technologies